Smart Hive Technology: What Beekeepers Install Now

UC Riverside researchers developed a temperature sensor system that costs under $50 per hive and predicts colony health problems days before traditional inspection would catch them. Commercial beekeepers report 50% reductions in labor costs after installing monitoring systems. A solar-powered network of identical smart hives operating across Poland, Canada, Germany, and Ukraine is collecting standardized data for machine learning models.

The smart hive market hit $142 million in 2026 and projects to reach $800 million by 2028. That's not venture capital hype. That's working beekeepers spending real money on sensors because the data solves actual problems.

What Changed Between 2020 and 2025

Five years ago, hive monitoring meant expensive custom systems or DIY projects for tech-savvy beekeepers. Prices ran $400-800 per hive for comprehensive monitoring. Installation required technical knowledge. Commercial beekeepers experimented cautiously. Hobbyists mostly skipped it entirely.

2026 looks different. ApisProtect offers commercial monitoring for $3 per hive monthly. BroodMinder sells temperature/humidity sensors for $35-110. Complete monitoring setups including scales run $150-300 per hive. Solar-powered systems eliminate battery maintenance. Plug-and-play installation takes under a minute for most devices.

The European B-GOOD research initiative spent five years developing monitoring systems with 13 countries' researchers. They created digital combs - thin circuit boards equipped with sensors - that fit into standard frames. Bees build comb around them. The sensors transmit real-time data showing temperature, humidity, weight changes, and movement patterns.

That research moved from lab to field. Companies now manufacture versions of these systems commercially. The technology transitioned from "interesting research project" to "operational beekeeping tool" somewhere around 2023-2024.

What These Systems Actually Monitor

Temperature remains the foundational metric. Honeybees maintain precise internal hive temperatures between 33-36°C (91.4-96.8°F) for proper brood development. Temperature fluctuations indicate problems before visual inspection reveals them. A temperature sensor positioned on top of frames catches heat rising from the brood nest.

Colonies in distress can't regulate temperature properly. Disease, pesticide exposure, food shortages, or failing queens all disrupt temperature control first. The bees stop maintaining that narrow range. A sensor reading temperatures outside normal parameters three days running suggests intervention needs.

Weight tracking reveals nectar flow timing, food consumption rates, swarming events, and robbing behavior. Bees departing on foraging flights create predictable morning weight drops. Incoming nectar shows as steady weight gains through the day. A sudden multi-pound weight loss mid-morning indicates swarming - you can quantify when it happened and how many bees left.

Winter weight tracking matters more than summer. Colonies burning through stores faster than expected signal trouble. The scale shows consumption rates letting beekeepers time emergency feeding before starvation kills the colony. One beekeeper's report noted dropping from 100% winter losses to under 5% after installing scales and monitoring consumption patterns.

Humidity data combines with temperature to indicate colony population and brood levels. Strong colonies with lots of bees and active brood show different humidity patterns than weak colonies. Automated analysis can predict colony strength from these combined metrics without opening the hive.

Acoustic monitoring - recording hive sounds - detects queenless conditions, identifies pest problems, and tracks bee activity levels. Research published in 2026 shows specific sound frequency patterns correlate with colony health status. The 100-500 Hz range carries particularly useful diagnostic information.

The Commercial Adoption Pattern

ApisProtect targets commercial beekeepers explicitly, offering labor efficiency improvements up to 50% and transportation cost reductions to 25% during pollination. Commercial operations managing thousands of hives can't physically inspect every colony regularly. Monitoring data triages which hives need attention.

One commercial beekeeper quoted in ApisProtect materials noted hour-and-a-half drives to remote bee yards. Without monitoring, you drive there hoping everything's fine or responding to obvious problems already severe. With monitoring, you drive there knowing which specific hives need intervention. The alert system flags issues while they're still fixable.

Commercial pollination contracts add urgency. Almond growers specify colony strength requirements. Beekeepers need colonies at specific population levels by specific dates. Monitoring data tracks whether colonies are building properly or falling behind schedule. That early warning enables interventions - adding brood frames from strong colonies, providing supplemental feeding, requeening weak hives - when corrections still work.

The $3 monthly per-hive cost for ApisProtect's commercial service runs $36 annually. A single prevented colony loss covers 5-10 hives' monitoring costs depending on bee prices. Labor savings from reduced unnecessary inspections often exceed monitoring costs in year one.

Smaller operations and hobbyists follow different math. Someone managing 10 hives might spend $1,500-3,000 on complete monitoring setups. That's meaningful money compared to the hive investment itself. But the hobbyist beekeeper also can't afford 50% colony losses. Two colonies saved at $200-300 replacement cost pays for basic monitoring. The calculation works if the technology actually reduces losses.

What the Data Actually Shows

The UC Riverside Electronic Bee-Veterinarian (EBV) system demonstrated predictive capabilities in controlled testing. Researchers monitored 25 hives, tracking temperature patterns against colony health status. The system calculated a "health factor" from 0-1, with 1 meaning full-strength colony.

When the health factor dropped below empirical thresholds, researchers contacted the apiary manager. Physical inspection confirmed problems the sensor data predicted. The system caught issues requiring intervention before visual symptoms appeared obvious. That's the value proposition - early detection while intervention still works.

European HIVEOPOLIS research developed digital combs that do more than monitor. These can be activated to heat specific hive areas remotely. During winter, colonies sometimes die from cold trying to reach honey stores just out of reach. Heating specific comb areas helps bees access food reserves. Initial trials show swarm intelligence responds to the temperature changes by reducing bees' own heat production, saving colony energy.

The global smart hive network operating across multiple countries collects standardized data from identical hive designs. Solar-powered IoT devices transmit weight, internal/external temperature, humidity, GPS position, and technical parameters continuously year-round. This creates the homogeneous dataset necessary for training machine learning models.

One documented use case: honey robbing prediction. Robbing behavior - strong colonies attacking and stealing from weak colonies - involves swarm intelligence elements. The monitoring network identified robbing through distinctive weight and temperature patterns. Predictive models now forecast robbing events before they start, enabling beekeepers to protect vulnerable colonies.

The Technology Tiers

Bottom tier: DIY solutions and basic single-function monitors. Make Magazine published open-source plans for sensor-based monitoring. Hobbyists with technical skills build systems from off-the-shelf components. Cost runs $50-150 per hive depending on sensor selection and feature set. This approach works if you enjoy the building process and can troubleshoot problems.

Mid-tier: Commercial modular systems like BroodMinder. Temperature/humidity sensors cost $35-110 depending on model and features. Weight scales run $280. Wireless hubs for data collection cost $110-275. A complete setup monitoring one hive runs $150-300 total. These systems use Bluetooth Low Energy communication requiring no wiring. Sensors last a year or more on coin cell batteries.

BroodMinder positions itself as the "affordable, industry-leading" solution with over 17,000 devices delivered. The company focuses on simple, uniform measurements across many hives. Data syncs through free smartphone apps or web platforms. Basic plans cost nothing beyond hardware purchase. Premium subscriptions add features but aren't mandatory.

Top-tier: Integrated professional systems like Arnia (UK) or ApisProtect (Ireland). These provide complete monitoring packages with advanced analytics, predictive algorithms, and professional support. Arnia gained recognition as the "gold standard" in monitoring circles for real-time tracking capabilities. The company developed mathematical formulas characterizing swarming behavior - something beekeepers thought impossible until the data proved otherwise.

Pricing for premium systems runs higher, though exact numbers vary by scale and contract terms. Commercial beekeepers report these systems cost more upfront but deliver the most sophisticated analytics and support. The target market runs larger operations where monitoring hundreds or thousands of hives justifies premium pricing.

What Stops Wider Adoption

Cost remains the primary barrier for small-scale beekeepers. Spending $300-500 per hive on monitoring when the hive itself cost $150-300 requires conviction the technology delivers value. First-time beekeepers especially hesitate - they're still learning basic hive management and can't evaluate whether sensor data will actually help.

Connectivity challenges affect remote apiaries. Many monitoring systems require cellular service or wifi for data transmission. Apiary locations often lack reliable coverage. Some systems use LoRaWAN (long-range wide-area network) communication designed for IoT devices in remote locations, but that requires installing gateway infrastructure. Solar power solves battery life problems but adds cost and deployment complexity.

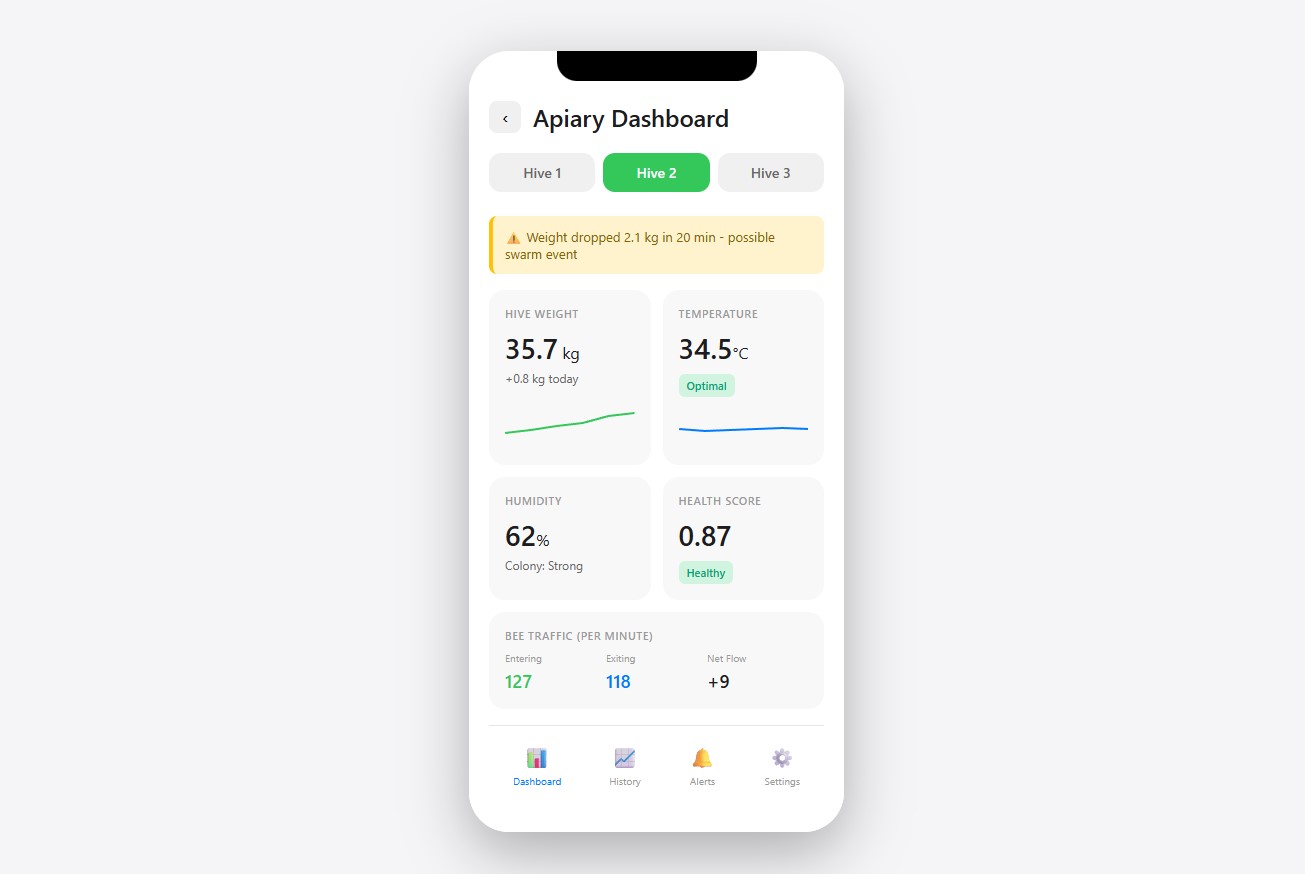

Data literacy matters more than most realize. Having sensor data doesn't automatically translate to understanding what it means. Temperature reading 32°C - is that good or concerning? Weight dropping 2 pounds overnight - swarming, robbing, or normal foraging activity? Humidity at 65% - does that indicate proper colony size or potential problems?

The systems that succeed provide interpretation alongside raw data. Simple visual indicators - green/yellow/red status, health scores from 0-100, alerts only when action needed - work better than dumping spreadsheets of measurements at beekeepers. The analytics layer adds value beyond the sensors themselves.

Learning curves compound the adoption barrier. Even "easy" systems require learning apps, understanding connectivity options, configuring alerts, interpreting dashboards. Beginning beekeepers face enough learning already. Adding technology complexity sometimes pushes past their capacity to absorb new information.

Traditional beekeepers resist on principle. Beekeeping worked for centuries without sensors. Opening hives, inspecting frames, observing bee behavior - that's real beekeeping. Monitoring devices feel like outsourcing skills that should live in the beekeeper's eye and experience. This perspective isn't necessarily wrong, just different.

The 2025 Colony Crisis Amplified Interest

2026's winter colony losses hit 55-70% across large swaths of US beekeeping. Some commercial operations lost 90% of colonies. This represents the worst losses since tracking began, creating desperate demand for anything helping reduce mortality.

Smart monitoring systems can't prevent all losses. Varroa mites, pesticides, poor nutrition, climate extremes - these problems require intervention beyond data collection. But monitoring can identify struggling colonies early enough that intervention still works. That's valuable when traditional management just watches colonies decline without catching problems until they're terminal.

The crisis shifted cost-benefit calculations. When you're replacing 60% of colonies annually, monitoring technology that reduces losses to 30-40% pays for itself immediately. The insurance value outweighs the cost. Beekeepers who were considering monitoring for years suddenly installed systems spring 2026.

Package bee shortages during 2026's crisis made colony preservation more urgent. When replacement bees sell out by February and you're waitlisted hoping for cancellations, keeping existing colonies alive matters more than ever. Monitoring technology became colony preservation insurance rather than optional efficiency improvement.

What Actually Works vs Marketing Claims

Temperature monitoring delivers consistent value. The data clearly indicates colony presence, rough population estimates, and brood activity patterns. Experienced beekeepers learn to read temperature traces almost as precisely as physical inspection reveals. This technology works reliably.

Weight tracking provides actionable data if conditions are right. Hives on solid, level surfaces with stable scales produce useful measurements. Hives on uneven ground or with scales affected by wind, rain, or animal interference produce noisy data requiring heavy interpretation. When it works, weight data is excellent. When conditions aren't ideal, it's frustrating.

Humidity sensing shows promise but interpretation remains less clear than temperature or weight. Research demonstrates humidity patterns correlate with colony strength and brood levels, but translating those patterns into management decisions requires more data and analysis. The technology works, the application knowledge still develops.

Acoustic monitoring exists primarily in research contexts. Some commercial systems offer sound analysis but this remains the least mature monitoring category. The research showing acoustic signatures can predict colony status is solid. Building consumer-grade systems that implement this reliably at reasonable cost hasn't happened yet.

Predictive algorithms generate the most controversy. Claims about predicting swarming days in advance, identifying disease patterns, forecasting honey production - these range from "actually works" to "aspirational marketing" depending on the system and specific claim. The technology exists to build these predictive models. Whether specific commercial products deliver on their promises varies.

The Research Foundation Building Future Systems

A systematic literature review published in 2026 analyzed 135 peer-reviewed publications on smart beehive technology from 1990-2025. Health assessment remained the dominant research goal throughout, with behavior detection showing steady increases in attention, particularly in 2024-2026.

The research focuses on IoT-based monitoring, sensor modalities, machine learning techniques, and precision apiculture applications. Common sensor types span environmental, acoustic, visual, and structural modalities supporting health assessment, behavior analysis, and forecasting. Studies increasingly combine multiple sensor types with advanced analytics for more comprehensive colony monitoring.

Geographic distribution of research and implementation shows concentration in upper-middle and high-income economies. North America holds 38% of the smart hive market share, driven by large-scale commercial operations. Asia-Pacific shows fastest growth, particularly China's automated honey production operations.

The research gap analysis identifies needs: comprehensive population monitoring across greater species diversity, improved understanding of pesticide mixture effects, climate change vulnerability assessments for pollinators, economic valuation of monitoring system ROI, optimal habitat design specifications, and long-term effectiveness evaluation of smart monitoring interventions.

Universities receive substantial funding for smart hive research. Appalachian State's Beemon system earned a $641,951 grant for commercialization. The UNC System supports multiple beehive monitoring projects. European research initiatives like B-GOOD and BETTER-B receive multi-year EU funding. This research investment indicates continued technology development and refinement.

What's Coming 2025-2030

Fully automated predictive hives represent the next development stage. Current systems monitor and alert. Next-generation systems will monitor, predict, and intervene automatically. Temperature control triggered by algorithms. Automated mite treatment dispensed based on population models and infestation thresholds. Feeding systems activated by consumption rate analysis.

ToBe's HiveMaster device previews this direction. The system automatically administers anti-Varroa treatment in controlled pulses based on integrated sensors, data analytics, and AI protocols. Independent trials showed 95% efficacy against Varroa mites - double the efficacy of conventional treatments. The device requires no maintenance for a year and communicates through smartphone apps for remote diagnostics.

AI-driven disease prevention will combine monitoring data with machine learning trained on thousands of colony health datasets. Systems will recognize disease signatures early, recommend specific interventions, track treatment effectiveness, and refine algorithms continuously as more data accumulates.

Blockchain integration for honey traceability and supply chain transparency couples smart hive monitoring with product authentication. Sensors tracking production combined with blockchain recording creates verifiable supply chain documentation valuable for premium honey marketing.

5G and satellite connectivity expand remote monitoring capabilities. Current systems struggle in areas lacking cellular coverage. Low-earth-orbit satellite networks and 5G deployment will enable monitoring in previously unreachable locations. This matters for commercial beekeepers managing apiaries across wide geographic areas.

Biosensors for pathogen detection represent active research areas. Sensors that directly detect disease organisms rather than inferring problems from temperature or weight changes would enable even earlier intervention. Some systems under development can identify specific pathogens from hive air samples or bee traffic patterns.

The Split That's Developing

Beekeeping is fracturing between data-driven and traditional approaches. One group embraces monitoring technology, trusts algorithmic recommendations, optimizes based on dashboard analytics. The other group opens hives, observes bees directly, makes decisions from experience and intuition.

Neither approach is intrinsically superior. They serve different scales and philosophies. Commercial operations managing thousands of hives can't function without monitoring - physical inspection of that many colonies isn't feasible. Hobbyists managing 2-10 hives often prefer the hands-on approach - they're beekeeping partly for the experience of working with bees directly.

The tension appears in online discussions, beekeeping conferences, and local association meetings. Traditional beekeepers dismissing monitoring as unnecessary gadgets. Tech-focused beekeepers questioning how anyone manages colonies without data. The divide sometimes splits generational lines - younger beekeepers adopting technology faster than older practitioners who learned beekeeping pre-internet.

But mixed approaches emerge too. Beekeepers using monitoring on some hives to establish baseline patterns, then managing additional hives traditionally with monitoring data informing their observations. Using weight scales but not temperature sensors. Adopting certain technologies while skipping others that don't match their management style.

The Economic Reality Check

Smart hive technology works. The question isn't whether it provides value - documented colony loss reductions, labor savings, and improved honey yields prove the value proposition. The question is whether that value justifies the cost for specific beekeeping operations.

A commercial operation replacing 60% of 1,000 colonies annually ($300 per colony replacement) spends $180,000 on bees alone. If monitoring technology costing $3-10 per hive monthly reduces losses to 30%, it saves $90,000 annually. The technology pays for itself in year one even at the high end of the price range.

A hobbyist managing 5 hives losing 60% annually spends $900 replacing colonies. Monitoring those 5 hives costs $1,500-2,500 upfront for complete systems. Reduced losses might save $450 annually. The payback period extends to 3-6 years. That calculation works if you're committed to beekeeping long-term. It doesn't work if you might quit after a couple frustrating years.

The market will stratify. Premium monitoring systems serving commercial operations willing to pay for comprehensive analytics and support. Mid-range modular systems serving serious hobbyists and small commercial operations wanting specific functionality without premium pricing. Budget DIY solutions serving tech-capable beekeepers prioritizing cost savings.

Some beekeepers will continue without monitoring entirely, managing colonies through traditional observation and accumulated experience. This approach works, it always has. Smart hive technology adds capabilities and changes what's possible. It doesn't make traditional beekeeping obsolete.

The rise of smart hive technology represents transformation, not replacement. Beekeeping is gaining new tools, new capabilities, new ways to understand colonies. Some beekeepers will adopt everything. Some will adopt nothing. Most will land somewhere between, using technology where it solves problems they actually face while maintaining hands-on practices where direct observation serves them better than sensor data.

That middle path - technology when it helps, tradition when it works - probably represents the future more accurately than either extreme of fully automated hives or complete technology rejection.